Power of Proximity: The RFID Revolution!

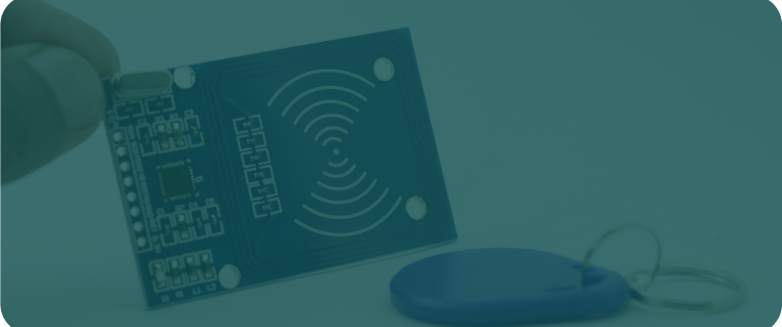

As RFID technology experts, we excel at crafting and implementing intricate and extensive deployments. Our RFID solutions include a robust hardware portfolio featuring high-performance RFID readers, printers, and tags, ensuring a seamless hardware implementation and integration experience while addressing your specific business needs.

Technology Highlights

Components

Frequently Asked Questions?

Does your solution support Barcode & RFID technology ?

What are some common applications and use cases for RFID technology?

What are RFID solutions for the manufacturing industry?

How can enterprises leverage RFID technology?

What are the key advantages of implementing RFID?

How do RFID Tags work?

Is the RFID tag different from FASTag?

Is RFID technology secure and private?

Loading...