Experience Unprecedented Accuracy and Speed!

Embark on a transformative journey with our innovative machine vision solutions that seamlessly integrate the capabilities of Artificial Intelligence and Machine Learning. Our machine vision system offerings empower your enterprise to automate and optimise production processes to enhance quality control.

Technology Highlights

Use Cases

Gauge

Precise Dimensioning | Fill level Monitoring | Automated Metrology | Edge Detection | Colour verification

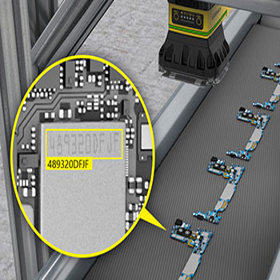

Identify

Part Identification | OCR & OCV | Code Verification (1D and 2D) | Label Inspection | Part Traceability

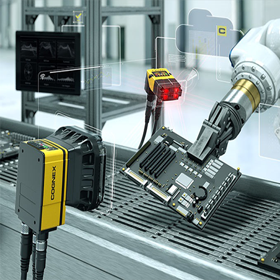

Guide

Robot Guidance | Alignment and Orientation | Pattern Matching | Precision Assembly | Position Verification

Inspect

Defect Detection | Surface Inspection | Optical Inspection | Packaging Inspection | Contaminant Detection